New Zealand Garden Diary: Making a $100 Shed From Recycled Materials With Hand Tools

I’ve done it. I’ve (nearly) finished my potting shed. Almost everything has come from the renovations we've done on the house. The wood framing/deck/plywood was leftover from rebuilding the back room, replacing the floor in the bedroom and replacing the veranda. The windows are the ones we replaced when we put in double glazing. The corrugated iron cladding and roof are from when we replaced the veranda roof. I bought old hinges from the eco-shop on Blenheim Road. The only new materials were nails and screws. All up, the shed cost me about $100 in money, but a lot of hours in time.

I used an electric drill with various bits (great for putting in screws… and taking them out again), but other than that I only used hand tools: tin snips, handsaw, chisel, hammer, crowbar (to remove the roofing nails when I had to rejig the roof).

The potting shed was inspired by Monty Don’s one in Gardener’s World

I read a book about building treehouses (How to Build Treehouses, Huts and Forts ) and watched a lot of YouTube videos to work out how to go about it (eg. this one and a bunch from My Self Reliance). Then I drew some plans to scale. They were more or less what I followed for the framing of the shed before I cut and attached the corrugated iron.

You can see my hand-drawn plans here and the following galleries show a step by step of how I did it.

Leveling (ahem!) and putting in treated wood as a foundation of sorts before laying board

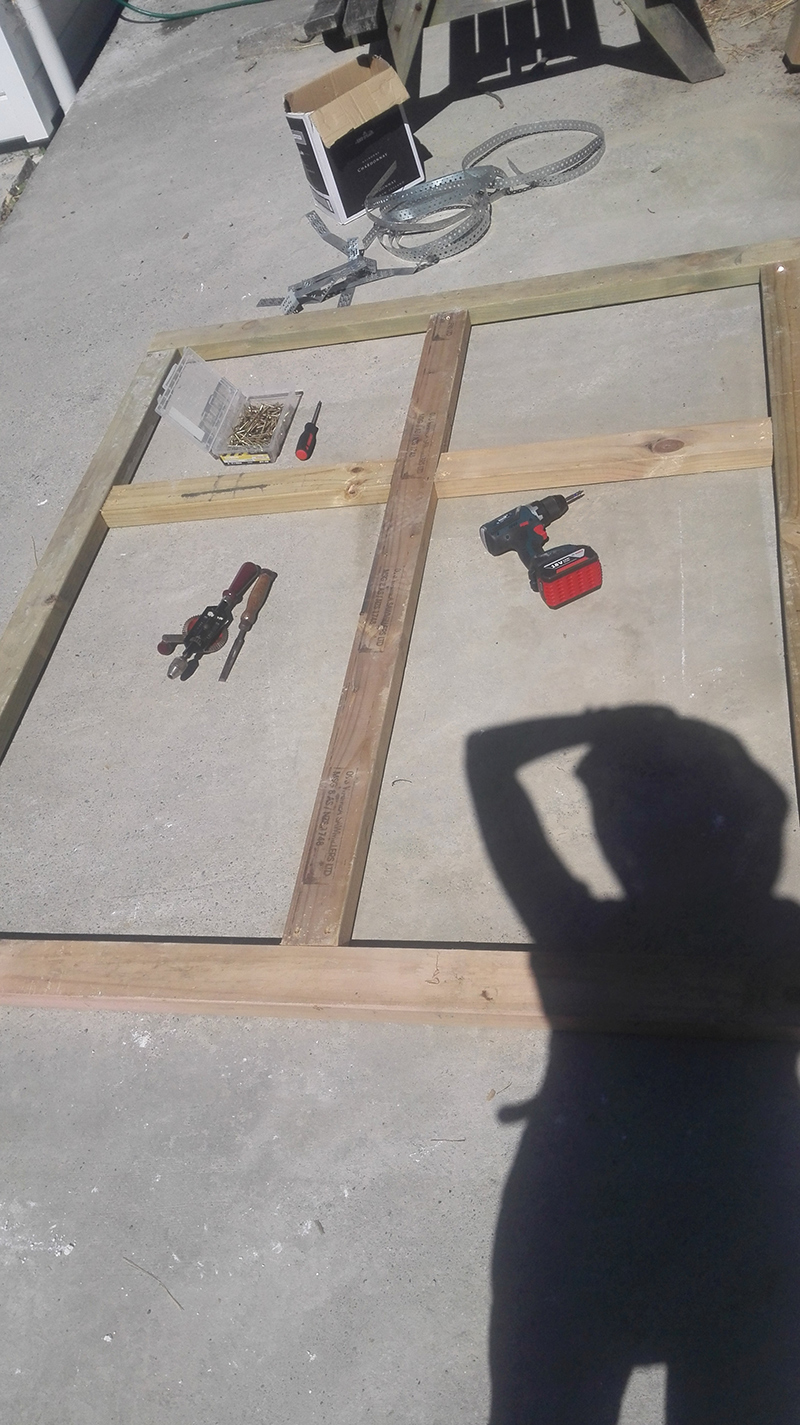

Measuring, sawing and screwing together the wood for the framing

I pre-drilled holes in the hard wood (pine was fine, though I used a chisel to allow the heads to be sunk). Screws are stronger and mean the shed can be taken apart.

Attaching boards to the rear of the frame and putting on the front frame

I used the old wall panelling for the back of the shed that won’t be seen. I’ll need to paint it with weatherproof paint.

Putting on joists for the roof

I chiselled out notches on the joists at the side of the shed, but just laid the other boards on top.

Putting on structural ply and finishing back wall

I started sawing to size and putting on the plywood that the corrugated iron would be attached to. It makes the shed stronger and makes it easier to screw in the tin.

Cutting tin and attaching it to roof joists

I bought some vintage tin snips on TradeMe and cut the iron by hand. It was hard work and perhaps new tin snips would have been better! I discovered later it is so much better to use hex bolt roof screws, as getting roof nails out of a roof with a screwdriver, hammer and crowbar is bloomin’ hard work.

Putting in windows

We have great views and I had glass I could use, so I put in some windows (using wood slats, not putty, to secure them). This is hard. I learned that you don’t screw/hammer anything in after the window has gone in as you’ll crack it! One window has been boarded further and I’ll need to replace another. But I have windows!

I made a door from screwing together floorboards and started attaching tin

Attaching tin is so much easier with hex bolts. I pre-drilled holes in the tin and then used the drill to screw in the bolts.

Making the roof look better

I wanted to shorten the overhang and attach tin to the underside. That meant I had to get the roof nails out. The only job worse than this was cutting the tin. I then reattached the shortened roof with screws.

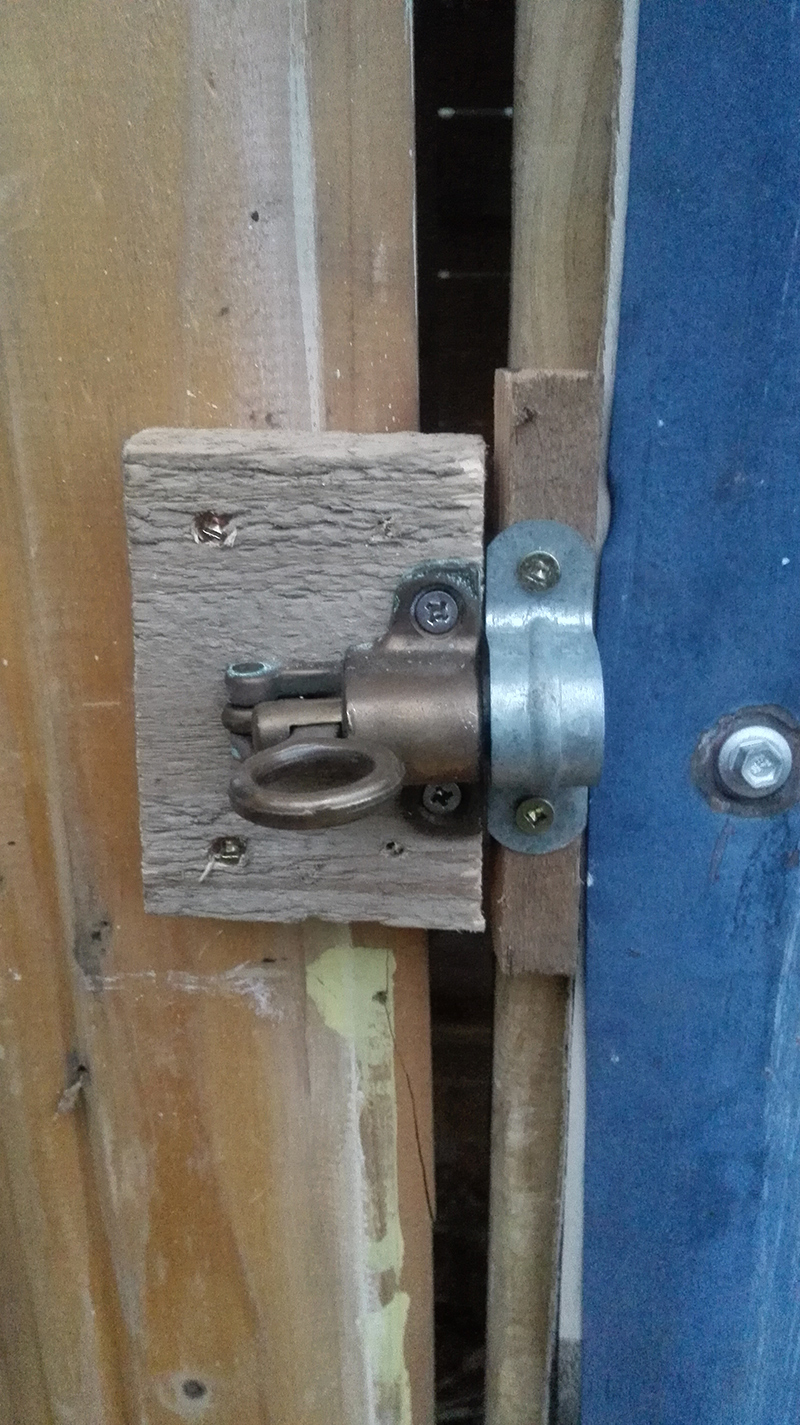

Attaching a deck and a door fastener

The deck is currently balanced on wood offcuts, as I’ll seat it properly on wood piles once the shed has been re-levelled. I bought the door latch from a garage sale in Lyttelton and found a thingy for it to go into at the eco-shop.

Here is the how it looks now (I just have to level it and finish the inside):

New Zealand Garden Diary: Composting and Bokashi

We haven't had a green waste bin ever since it disappeared with the tenants. Luckily we are on 1200 square metres and we can compost most of our green waste. What we can't compost (meat etc.) goes in the bokashi bin.

My friend, Felicity, says bokashi has been miraculous at improving her garden. I hope so as it is it is a lot of work to lug it up to the back section and dig it in. Bokashi works using anaerobic fermentation with effective microorganisms (lactic acid bacteria, yeasts, photosynthetic bacteria, actinomycetes and fungi according to biome.com.au).. These come in the form of a bran which you sprinkle over your food waste. The airtight seal on the bucket keeps the fermentation anaerobic and there is another bucket below to catch the liquid (which can be diluted and used as a plant food.

You can put in things you cannot put in compost like meat, cheese, fish and cooked foods like bread rice and pasta. The only thing you can't put in is liquids. Even bones can go in there and I put in the poor little mice that we trap in the kitchen cupboard. Once the bin is full, you can leave it to ferment longer or bury it in the garden straight away. It is like blood and bone on steroids.

Reasons to Be Cheerful - Building a Potting Shed From Recycled Materials

I read a few books, watched some YouTube videos and drew up some rough plans. Then I started to make my own shed. So far, I have put in a floor and framed three of the four walls. It is already a little wonky because, well, I’ve never built anything before and also I didn’t want to put in concrete. But that’s okay. It’s a shed, not a house.

New Zealand Garden Diary: Cecil's Successor - Cuthbert the Cucumber

This is a challenging year to grow cucumbers outdoors in Lyttelton. Not because of the shorter growing season (Lyttelton is inside an ancient volcanic crater and when the days get shorter we lose the sun before Christchurch does), but because we've had so little rain. I have planted Cuthbert in an area that I can soak with the hose. There is also a lot of mulch there. I prepared the ground by digging in masses of manure and compost well before I planted the cucumber. Last year, I got 15 cucumbers from Cecil. I've had one so far from Cuthbert, but he's got some time to catch up.